World’s Smallest 3D Bioprinter: A Breakthrough in Vocal Cord Regeneration

Discover how McGill University scientists created the world’s smallest 3D bioprinter (2.7 mm nozzle) for vocal cord tissue repair. Learn how it works, its medical significance, potential applications, and impact on regenerative medicine.

World’s Smallest 3D Bioprinter

In a groundbreaking medical innovation, researchers at McGill University, Canada, have developed the world’s smallest 3D bioprinter, specially designed for vocal cord tissue reconstruction during surgery. This pioneering tool, reported in the journal Device (October 2025), represents a remarkable advancement in minimally invasive bioprinting, potentially transforming the way surgeons repair delicate internal tissues in real time.

About the Development

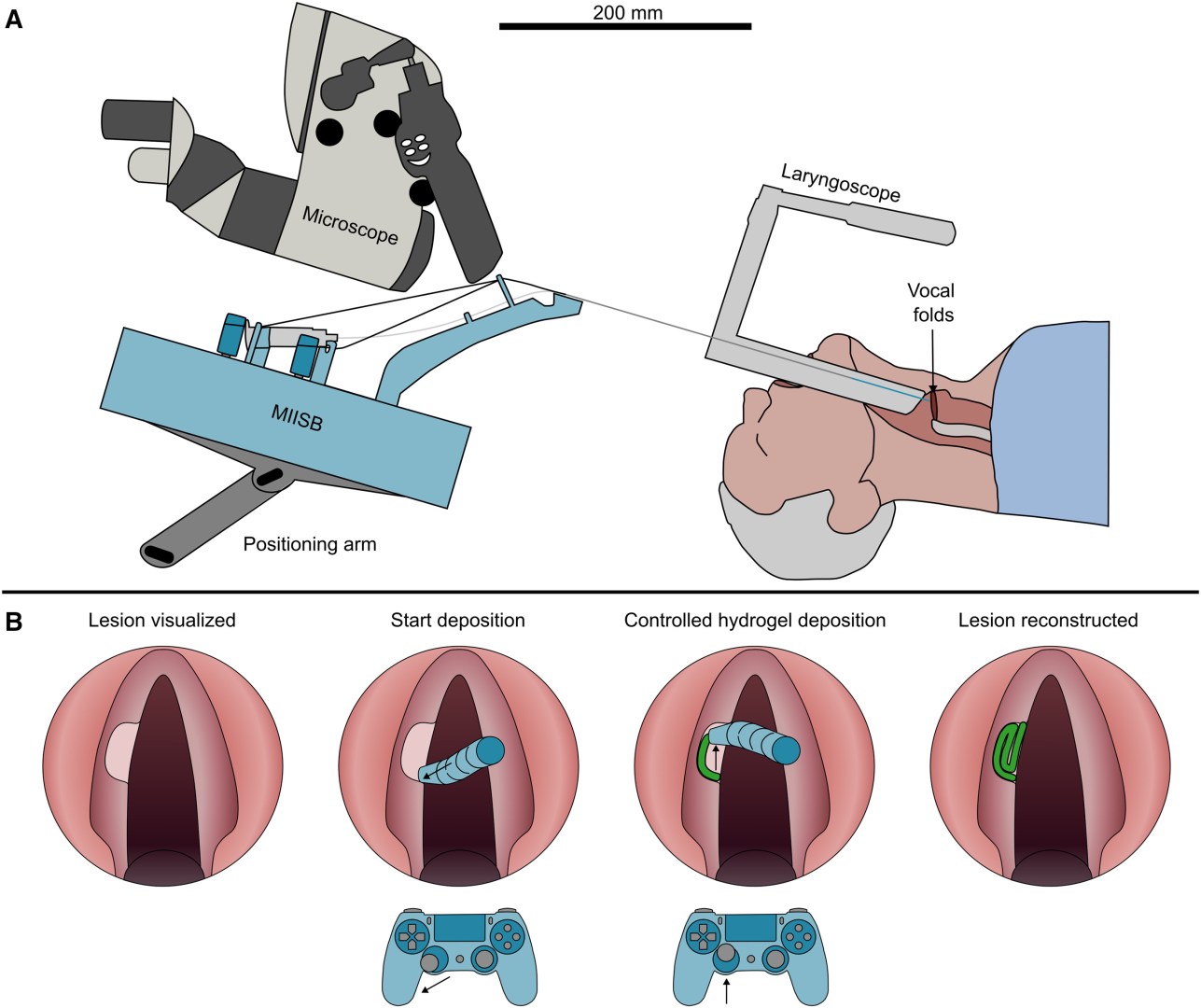

The innovation features a bioprinter nozzle just 2.7 mm in diameter, allowing surgeons to precisely print living tissue structures inside confined spaces like the human throat — a region too small for existing bioprinting technologies. The compact device has been engineered to fit within the surgical instruments used during laryngeal procedures, enabling in-situ tissue reconstruction.

Unlike conventional 3D bioprinters that operate in laboratory conditions, this device is designed for direct clinical use. It allows doctors to repair damaged tissues during surgery itself, rather than waiting for lab-grown tissues to be transplanted later.

How It Works

The miniature bioprinter functions by extruding biocompatible hydrogels directly onto the damaged vocal cord tissue. These hydrogels serve as scaffolds for new cell growth, promoting natural tissue regeneration while maintaining flexibility — a key factor for restoring voice function.

Key technical features include:

-

Nozzle Size: 2.7 mm — small enough to operate in the confined laryngeal region.

-

Printing Resolution: 1.22 mm — allows highly accurate deposition of materials on the damaged surface.

-

Design Inspiration: The bioprinter’s flexible, “trunk-like” structure (inspired by an elephant’s trunk) enables surgeons to maneuver it precisely under a surgical microscope.

-

Real-time Operation: Surgeons can directly visualize and control the printing process, ensuring precise tissue placement without damaging surrounding healthy structures.

This combination of miniaturisation, flexibility, and precision enables the creation of customized biological implants — directly at the injury site — during a single surgical procedure.

Why It’s Needed

Vocal cord injuries often lead to fibrosis (scar formation), stiffening, and loss of natural vibration, which significantly affects speech and quality of life. According to recent medical data, about 18% of patients who undergo vocal cord surgery experience such complications.

Existing treatments, such as hydrogel or fat injections, often fail to distribute evenly, leading to irregular tissue recovery and persistent voice problems. Moreover, traditional methods lack control over tissue shape and mechanical properties.

The new miniature 3D bioprinter addresses these challenges by:

-

Delivering controlled, uniform hydrogel deposition.

-

Restoring natural vocal cord shape and biomechanics.

-

Allowing personalised reconstruction for each patient’s anatomy.

-

Reducing the need for multiple surgeries or long-term rehabilitation.

This precision-driven approach could restore normal vibration and voice tone — a critical improvement for patients, especially singers, teachers, and speakers.

Potential Impact

The innovation’s potential extends far beyond vocal cord repair. In the near future, this micro-bioprinting technology could be adapted for other confined or delicate surgical sites such as:

-

Colon and intestinal walls (for reconstructive surgery after ulcers or injury).

-

Liver tissue (for localised tissue regeneration).

-

Eye and retina repair (for microvascular and corneal tissue engineering).

Researchers are now preparing for animal trials, followed by human clinical testing to evaluate the device’s safety, efficiency, and long-term functional outcomes. If successful, it could revolutionize microsurgery, regenerative medicine, and organ repair.

Significance

This innovation represents a paradigm shift in regenerative medicine. By enabling in-situ 3D bioprinting, surgeons can reconstruct damaged tissues directly inside the human body — without relying on external lab processes. The world’s smallest 3D bioprinter is not just a technological milestone but a symbol of how engineering and biology are converging to redefine the future of surgery.

The device demonstrates how bioprinting precision, flexibility, and personalization can revolutionize healthcare — from voice restoration to full organ regeneration — making it one of the most promising medical innovations of the decade.

Subscribe to our Youtube Channel for more Valuable Content – TheStudyias

Download the App to Subscribe to our Courses – Thestudyias

The Source’s Authority and Ownership of the Article is Claimed By THE STUDY IAS BY MANIKANT SINGH